Training Services

Training Services

Our training is customized to meet specific needs and is provided on site. Basic level includes introduction to 3D measurement concepts and initial operation of the hardware and software. Advanced level covers concepts of GD&T, automation/batch inspection, auto-archiving data, SPC tools, additional sensors and 4-axis & 5-axis part inspection.

We provide Basic to Advanced training on both Micro-Vu and LMI machines. Training is structured to meet your team’s needs and current level of capabilities. All training takes place on site with your system and applications.

Micro-Vu Basic Training

4 hours at your machine

- 1st hour: Introduction & brief overview of the system’s function and capabilities

- 2nd hour: Hands on training using training part provided – involving primarily programmers (Training part is first used because it is discussed in the tutorials and should be used for practice during interim period of days between training sessions)

(Optional 10 minute break) - 3rd hour: Training/programming focusing on your specific part challenges

- 4th hour: Practice of part inspection utilizing new program(s), plus data reporting

Micro-Vu Advanced Training

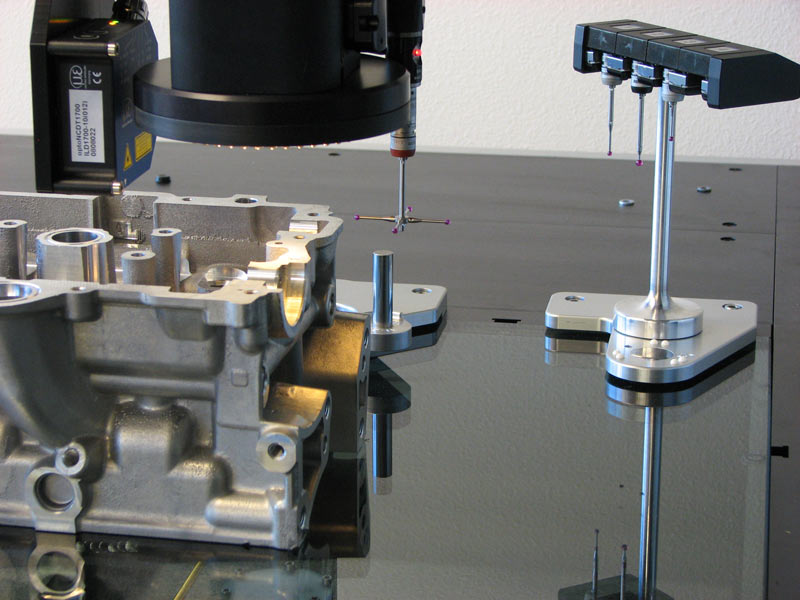

In this session, we first refresh core concepts from basic training and review if necessary. We address questions and challenges encountered during interim period since the basic training was conducted. Then, we move ahead to cover advanced GD&T concepts, automated batch inspection, auto-archiving data, SPC tools, and additional sensor technologies (touch-probe and laser) if equipped. The advanced training is customized to meet the clients’ specific needs and level of proficiency.

Consulting Services

We provide measurement consulting and programming services for challenging projects, including on-site or web-based programming and consulting. These services can be a lifesaver on time-sensitive projects or for critical projects requiring highest accuracy and best repeatability possible. We also assist with measurement dispute resolution and correlation improvements.

Custom Fixturing Design

With 15+ years’ experience, we know what works and what doesn’t in customized inspection fixturing. By leveraging our CAD team and modern 3D printing technology aboard our SNAPFIXTURE platform, we can help you get it right the first time. Think efficient loading/unloading, optimized repeatability and reducing part handling/setup.

Calibration and Maintenance Services

We provide factory authorized calibration, preventative maintenance and repair services for Micro-Vu systems and others. All tasks are performed by a Factory Registered Metrologist. A full report is provided, including As-Found and As-Left performance data with PASS/FAIL indications. All hardware and artifacts used are traceable to N.I.S.T. and maintained in accordance with ISO 17025 standards. Next day service is often available.

Validation Services

System Validation is the first logical step towards full Test Method Validation of critical inspection activities. Our standard validation consists of Installation, Operational and Performance Qualification (IQ/OQ/PQ), including on-site execution by a Factory Registered Metrologist. A binder is created with tabbed sections to organize all of associated documents and incorporating client specific templates, letterhead and document control. Software Validation is a fundamental part of the OQ phase. Customized validations are available.